Rotating LED Globe – Where Precision and Innovation Merge

A rotating double sphere, equipped with 480 addressable RGB LEDs, generates impressive images and animations.

The basis is the so-called persistence-of-vision effect: the human eye «stores» the received light impulses for a short time. When the four semi-rings rotate fast enough and the LEDs display the appropriate colors at the right moment, a complete, seemingly floating image is created for the viewer.

The Rotating LED Globe is a great visual example of our development expertise: from requirements engineering to embedded hardware and software development through to the finished product.

How does it work?

In order to achieve the desired effect, hardware, software and mechanics must be perfectly coordinated. Below is a brief explanation of the individual components included in the Rotating LED Globe, along with their main challenges.

Mechanics

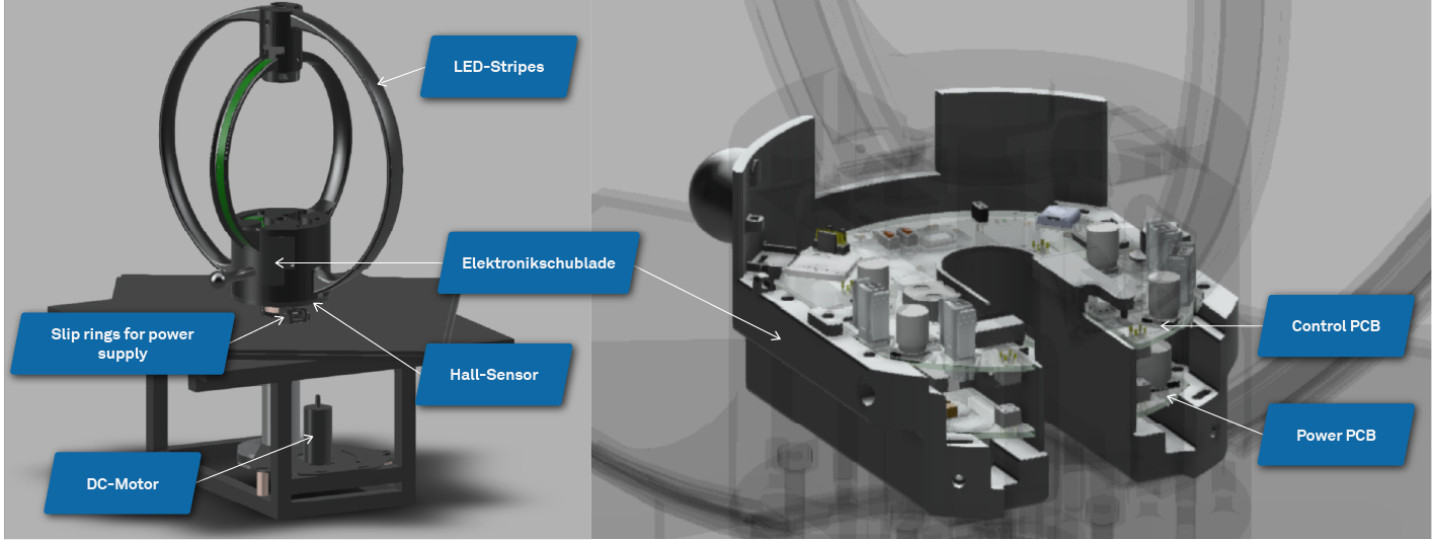

The mechanics consist of a stationary frame and a rotating rotor.

The 3D-printed rotor carries the LED semi-arcs as well as the control and power PCBs. Energy is transferred via slip rings, while a DC motor drives the rotor at 750 rpm. This enables a refresh rate of 25 FPS with two fields.

The challenge lay in developing a compact and stable design with an extendable drawer for the electronics, which could be manufactured using 3D printing.

The rotor consists of two circular rings offset by 90°, allowing optimal placement of the flex PCBs. Rotation is counter-clockwise to ensure image construction from left to right.

Thanks to our experience, we were able to develop all these system considerations and the basic construction ourselves. For the finishing touches and production, we relied on our partners.

The Electronics

The heart of the globe is the electronics, which consist of three core components:

Power PCB, Control PCB and the LED strips.

Power PCB

The Power PCB is primarily responsible for supplying the Control PCB and the LED strips. It converts the 24 VDC from a standard industrial power supply into the three required voltage levels.

The challenge in the design was to develop DC/DC converters with high efficiency. This was essential to provide the LED strips with sufficient power without generating excessive heat.

Through prior simulations, we were able to identify a suitable converter and, in combination with sophisticated placement, dispense with active cooling.

Controller PCB

The Controller PCB controls all functions of the globe. It handles reading the images from the SD card, image output, communication and synchronization with the rotational movement. This was implemented with a powerful STM32H7 microcontroller. The board also integrates a UHS1 SD card slot for reading image data.

Precise synchronization takes place via a Hall sensor and hardware timers, which adjust the image output exactly to the rotation speed. An ESP32 module was also provided for wireless functions for later expansions.

The main challenges during design were the very limited space and the need for impedance-controlled routing of the clock and data signals for serial LED control.

By specifically optimizing the signal paths, coordinated track widths and layer stack-up, we were able to successfully address both points.

LED Strips

Two flex PCBs equipped with LEDs were developed for each of the outer and inner rings. The LEDs on the strips were divided into individually addressable segments.

The large dimensions of the strips made the uniform distribution of the power supply for the LEDs a challenge. They had to be dimensioned in such a way that they could reliably transmit the required current intensity.

Furthermore, impedance-controlled routing for the clock and data signals was also necessary here in order to be able to control the LEDs at the required speed.

Software

The software forms the brain of the Rotating Globe and is the link between hardware, image data and movement.

It runs on the STM32H7 microcontroller of the Controller PCB under FreeRTOS. The architecture is based on the CSA C++ Building Block Framework, which enables a modular, maintainable and thread-safe structure.

The software handles image selection from playlists that can be created, processes real-time data from the Hall sensor for synchronization with the rotation and controls the LED output.

A corresponding Python script was created for preparing the images on the PC. Alternatively, the embedded software also supports the display of the current time based on the integrated Real-Time Clock (RTC).

The main challenges of the software were the hard real-time requirements and the limited processing time. We mastered these through the clever use of DMA and hardware timers as well as our experience in resource-limited and hardware-oriented embedded software development.

Our Success Factors

Everything starts with a vision: a rotating LED globe that lets images and animations float seemingly freely in space. To make this idea a reality, it takes more than creativity. It takes structure, precision and teamwork.

We started with a clear foundation: clean requirements engineering. This ensured that all system and interface requirements were defined from the start. Building on this, we developed detailed specifications for hardware, software and mechanics.

In hardware design, we relied on our many years of experience from various development projects with low-power, high-speed and communication requirements. We combine this with our internal processes and tools such as Altium Designer.

Embedded software development, as one of our core competencies, is in our blood and in combination with our CSA Embedded Toolchain, results in innovative, maintainable and tested code at the highest level.

And finally, our know-how in the area of project management ensured that all disciplines played together perfectly and resources were used efficiently.

Conclusion

How do you show what you can do?

For us at CSA Engineering AG, this question is central.

As an engineering office with a focus on embedded systems, we implement complex customer projects every day. But sometimes it takes more than a data sheet or a project report – it takes something you can see, experience and understand.

With the Rotating LED Globe, we have created exactly that:

A technological showpiece that makes our strengths visible – innovation meets practice, technology meets design. We develop tailor-made solutions that not only work reliably, but inspire and create real added value.

Thanks to our expertise in requirements engineering, systems engineering, embedded hardware and software development combined with project management adapted to the needs, we bring your ideas to market maturity safely and efficiently.

Do you see yourself in one of these areas?

Then do not hesitate to contact us and together we will find a suitable solution for your challenge.

Contributors from our team:

Adrian Annaheim - Embedded Software Engineer

Lukas Frei - Embedded Software Engineer

Roland Schenk - Embedded Software Engineer

Pascal Hari - Embedded Software Engineer

Nicola Jaggi - Embedded Software Engineer

Vanessa Järmann - Hardware Developer

Adrian Sallaz - Hardware Developer

Michael Lüthy

MSc FHNW in Engineering

Requirements Engineer & Project Manager

About the author

Michael Lüthy is project manager and requirements engineer at CSA Engineering AG. With his expertise in project management and requirements engineering, he ensures that complex ideas are implemented in a structured manner—from the initial requirements to the finished product.